While fitting the monitor was awkward, the Control Panel was just downright annoying

if I'm honest and it was made doubly difficult by the fact that it was made

of metal. Had it been a wooden panel I would just have taken some measurements

from it and built a brand new one, but as you can see

here

it is a quite complex, moulded unit with a hinge all along its length and lots of extra

fixings and fastenings and holes drilled out for the speakers. All of that

meant that having a new piece fabricated was out of the question and I would

have to work with this one.

The problem was that the cab in its original state had this control layout with just two buttons and a trackball in the middle. When I got the cab it had already been modified and had extra controls added to it such as two more buttons and a joystick. This meant that all the holes drilled in the panel were in the wrong places for my new two player layout and I needed those filling in before putting my own holes in.

I toyed around with different ideas for getting back to a smooth had to go for the only and clean surface to put my own controls into because clearly a new panel was out of the question, a wood panel fastened to the top of the old one would leave exposed edges that would be both ugly and perhaps even sharp, so I decided on the only solution that would really work well and give me a good finish at the end.

The problem was that the cab in its original state had this control layout with just two buttons and a trackball in the middle. When I got the cab it had already been modified and had extra controls added to it such as two more buttons and a joystick. This meant that all the holes drilled in the panel were in the wrong places for my new two player layout and I needed those filling in before putting my own holes in.

I toyed around with different ideas for getting back to a smooth had to go for the only and clean surface to put my own controls into because clearly a new panel was out of the question, a wood panel fastened to the top of the old one would leave exposed edges that would be both ugly and perhaps even sharp, so I decided on the only solution that would really work well and give me a good finish at the end.

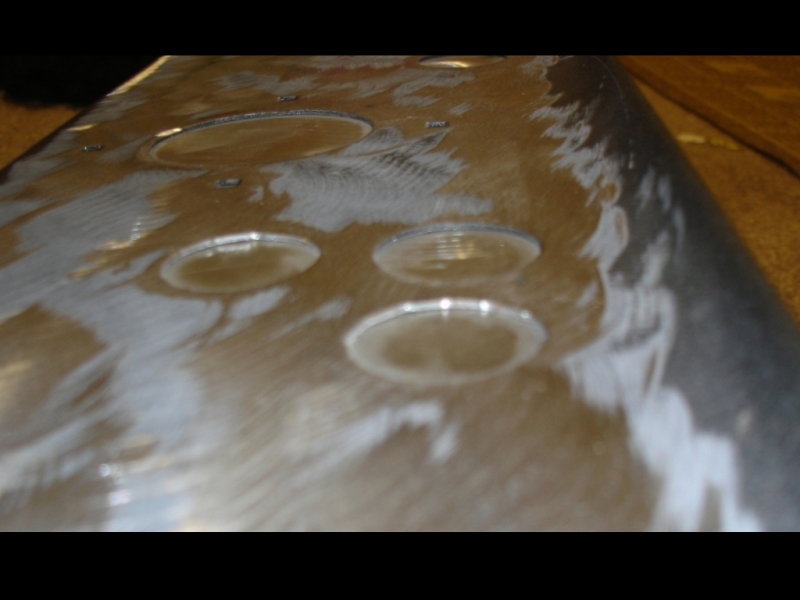

I got a friend of mine to weld a plate to

the underside of the panel which just left me some holes to fill so I took a trip to Halfords and bought some

Davids Isopon P38 (Bondo)

which is basically a fibreglass compound that you mix yourself before applying. Be warned though, this stuff really does

smell very strong and it should only be done in a well ventilated area, preferably with a respirator, or better still do

it outdoors as you can see I did. You mix it and apply

it with a plastic spreader and work it into all the areas to be filled and then leave for a couple of days to completely

go off and set rock hard.

Once it has set completely it needs to be sanded down before a finish can be applied to it, and the finishes you can apply to it are now a little restricted. The best finish you will get on a panel like this is powder coating which is fine if you are just renovating an original cab and leaving the original controls on, but if you have used fibreglass filler to repair holes then you won?t be able to have it powder coated afterwards, and the only solution is to use paint.

The paint I decided to use was Hammerite which is very resilient, needs no undercoat, can be applied straight to rust and leaves a slightly dimpled finish. This suited my project as there are a couple of dents in it already and I may not get a flawless finish when I sand it, so any imperfections would be glaringly obvious with a smooth, high gloss finish. Happy with my decision though, here is where I made the first of two mistakes on my panel, one quite big one and one small one with annoying and time consuming repercussions.

I put a couple of coats of Hammerite on my panel and got a nice finish that I was happy with then left it to dry for a couple of days. Once dry I marked out the centres for my holes and drilled them out as you can see here. Now I needed to widen these holes out to 28mm to accommodate my buttons and joysticks, and to do it I bought a set of these bits.

The small one did its job really well, the medium one widened the holes a bit more quite easily, but the large one just didn?t make any impression at all. All it succeeded in doing was making the whole panel get hot and force the paint to start bubbling. The bit itself got really hot and a little burned out, so now I was left with a panel with bubbling and burned out paint and with holes too small to use.

That was mistake number one.

The next step was to give the panel back to the fabricator to drill the holes out for me but unfortunately he only had a 26mm drill bit that was suitable, so he drilled the holes out and I then had to use a half round file to open them out to the required 28mm. With that done I had to strip what was left of the paint from it and start all over again, only this time it was a little more tricky getting an even coat while painting around all the holes. Just as I had applied the final few brushstrokes and was trying to move the panel out of the way to dry again, I knocked it over and it hit the floor.

That was mistake number two.

Stuck into my brand new coat of paint was lots of dirt, some bits of fluff and a few chips. Mad at myself I left it to dry overnight and the next day set to work sanding it down for what seemed like the fourteenth time. This time though there were no hiccups (must be something to do with all the practise) and I got a good even coat on at last before it was time for a dry fit and it looked and fitted just great.

Once it has set completely it needs to be sanded down before a finish can be applied to it, and the finishes you can apply to it are now a little restricted. The best finish you will get on a panel like this is powder coating which is fine if you are just renovating an original cab and leaving the original controls on, but if you have used fibreglass filler to repair holes then you won?t be able to have it powder coated afterwards, and the only solution is to use paint.

The paint I decided to use was Hammerite which is very resilient, needs no undercoat, can be applied straight to rust and leaves a slightly dimpled finish. This suited my project as there are a couple of dents in it already and I may not get a flawless finish when I sand it, so any imperfections would be glaringly obvious with a smooth, high gloss finish. Happy with my decision though, here is where I made the first of two mistakes on my panel, one quite big one and one small one with annoying and time consuming repercussions.

I put a couple of coats of Hammerite on my panel and got a nice finish that I was happy with then left it to dry for a couple of days. Once dry I marked out the centres for my holes and drilled them out as you can see here. Now I needed to widen these holes out to 28mm to accommodate my buttons and joysticks, and to do it I bought a set of these bits.

The small one did its job really well, the medium one widened the holes a bit more quite easily, but the large one just didn?t make any impression at all. All it succeeded in doing was making the whole panel get hot and force the paint to start bubbling. The bit itself got really hot and a little burned out, so now I was left with a panel with bubbling and burned out paint and with holes too small to use.

That was mistake number one.

The next step was to give the panel back to the fabricator to drill the holes out for me but unfortunately he only had a 26mm drill bit that was suitable, so he drilled the holes out and I then had to use a half round file to open them out to the required 28mm. With that done I had to strip what was left of the paint from it and start all over again, only this time it was a little more tricky getting an even coat while painting around all the holes. Just as I had applied the final few brushstrokes and was trying to move the panel out of the way to dry again, I knocked it over and it hit the floor.

That was mistake number two.

Stuck into my brand new coat of paint was lots of dirt, some bits of fluff and a few chips. Mad at myself I left it to dry overnight and the next day set to work sanding it down for what seemed like the fourteenth time. This time though there were no hiccups (must be something to do with all the practise) and I got a good even coat on at last before it was time for a dry fit and it looked and fitted just great.

Copyright © JamesOnline.net. All rights reserved.