Although an initial view of the workings of a pinball machine are certainly daunting, they can be broken down into four main sub systems:

Basically, a few spares of the more common transistors and chips, a soldering iron, solder, desoldering braid or a desoldering gun, a logic probe and most importantly a digital multi-meter. Well, I say most importantly but what was actually most important was this Pin Repair Guide that takes you through each step of diagnosing and hopefully repairing issues on my machine.

When I first turned my machine on I could hear a coil locking on, and pretty soon I could smell a coil locking on, and that usually means an issue on the driver board, the CPU board or both, but before I could start to diagnose those, I had to go back and start at the beginning of the chain, the Power Supply board.

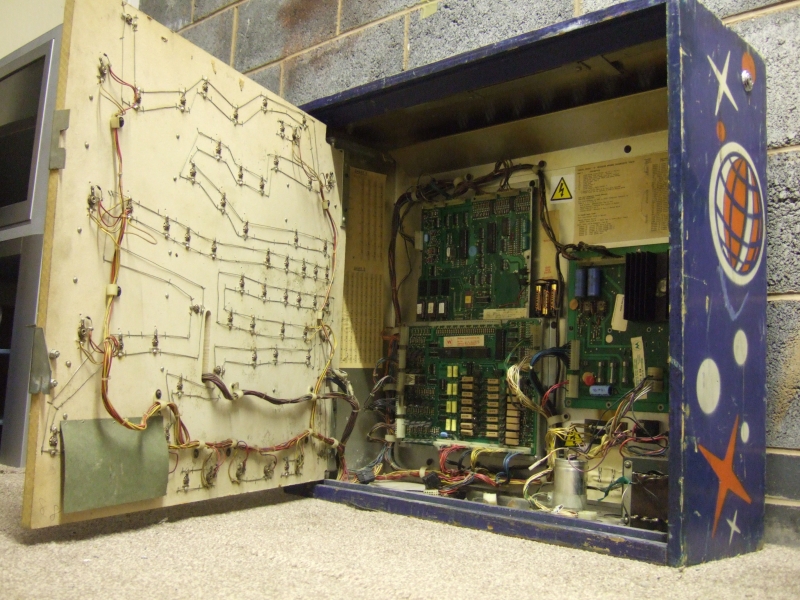

Looking at the back box (which is where all the fun begins) you can see the System 3 board layout, and all Williams System 3 to System 6 games share the same design architecture, a power board on the right and a "split board" design on the left which means that the CPU and driver functions run across two different boards. The thinking was that the driver board would be much more likely to fail and so a technician repairing a machine could simply swap the board for a new one have the old one repaired. Unfortunately, the method used to connect the two boards together was extremely prone to failure itself.

- Power Supply

- General Illumination (G.I.)

- Lamp circuit

- Solenoid circuit

Basically, a few spares of the more common transistors and chips, a soldering iron, solder, desoldering braid or a desoldering gun, a logic probe and most importantly a digital multi-meter. Well, I say most importantly but what was actually most important was this Pin Repair Guide that takes you through each step of diagnosing and hopefully repairing issues on my machine.

When I first turned my machine on I could hear a coil locking on, and pretty soon I could smell a coil locking on, and that usually means an issue on the driver board, the CPU board or both, but before I could start to diagnose those, I had to go back and start at the beginning of the chain, the Power Supply board.

Looking at the back box (which is where all the fun begins) you can see the System 3 board layout, and all Williams System 3 to System 6 games share the same design architecture, a power board on the right and a "split board" design on the left which means that the CPU and driver functions run across two different boards. The thinking was that the driver board would be much more likely to fail and so a technician repairing a machine could simply swap the board for a new one have the old one repaired. Unfortunately, the method used to connect the two boards together was extremely prone to failure itself.

They used a long strip of pins on the CPU board that the driver board would be pushed on to, but they did not always get a good, clean and consistent connection, and these pins carried high speed data from one board to the other, so if a single pin did not connect properly or was intermittently connecting then the game would lock up and be unplayable as the driver board would receive an incorrect signal from the CPU board and would perhaps fire a coil, or worse still, lock a coil on, which was what mine was doing.

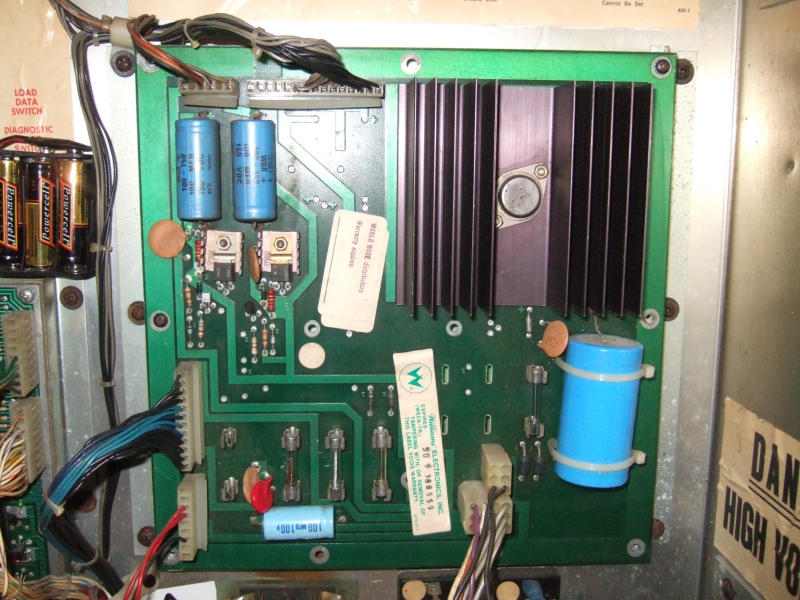

The Power Supply board in a pinball machine sends different voltages and currents to different parts of the machine, some of which are more sensitive than others. In the UK it takes 240 volts AC in to a transformer which then supplies the board with 18.6 volts AC and outputs +12 volts DC and +5 volts DC. It also takes in 90 volts AC from the transformer and outputs +/- 100 volts DC.

As well as the Power Supply board there are also two bridge rectifiers that supply unregulated 28 volts DC for the solenoids and 18 volts DC for the G.I. There is also a large capacitor in the back box that's used for the lamp matrix power.

The Power Supply board in a pinball machine sends different voltages and currents to different parts of the machine, some of which are more sensitive than others. In the UK it takes 240 volts AC in to a transformer which then supplies the board with 18.6 volts AC and outputs +12 volts DC and +5 volts DC. It also takes in 90 volts AC from the transformer and outputs +/- 100 volts DC.

As well as the Power Supply board there are also two bridge rectifiers that supply unregulated 28 volts DC for the solenoids and 18 volts DC for the G.I. There is also a large capacitor in the back box that's used for the lamp matrix power.

The first thing I had to check was that all of the incoming and outgoing voltages were correct on the relevant pins on the connectors, which initially they weren't, but a common failure is the capacitor on the Power supply board. This capacitor in question is a filter capacitor C15 which is the +12 and +5 volt logic filter capacitor whose its job is to smooth out the DC voltage after it has been converted from AC. If the DC voltage it emits is not smooth enough (picture a flat line on a heart monitor) then the CPU board will not boot properly and will potentially boot differently every time making troubleshooting extremely difficult.

Electrolytic capacitors like this have a working life of about ten years, so if mine was original to the table, which it appeared to be, then it was fitted in 1978 which makes it over 30 years old, three times its expected lifespan, so I replaced it as a matter of course. Don't even test it, change it.

It's worth noting that capacitor technology, like most things, has moved on and a replacement capacitor of the same or even a higher value will be much smaller in size than the original, so fitting it will need either a blob of silicone or a cable tie to fasten it to the power supply board in place of the older and larger one. Once I'd changed mine, all of the voltages were reading exactly as they should be, so I knew the CPU board was receiving the correct voltages.

Also on the power supply board are several fuses, and when first testing the game it's a good idea to pull these fuses out so that you are only powering up the power supply and none of the other boards or parts of table just in case there are problems elsewhere. One of these fuses in question was the G.I. fuse and as soon as I fitted a new one, the General Illumination bulbs came to life, well most of them anyway. An advisable modification for G.I. bulbs is to remove them all and replace them with a different bulb. Originally the table would have been fitted with #44s but they should all be replaced with #47s that will run much cooler and draw less power, therefore putting less stress on the bulbs, the circuits and the power supply. As a general rule the less heat generation you have in the game, the better.

Another advisable modification in the back box is to add a fuse to each of the two bridge rectifiers because it was essentially a design flaw not to include them in the first place, and one that Williams fixed in later machines. If either of the two bridge rectifiers (one for the lamp matrix and one for the solenoids) shorts out and the main fuse does not blow then the machine will set on fire, and that has happened more than once.

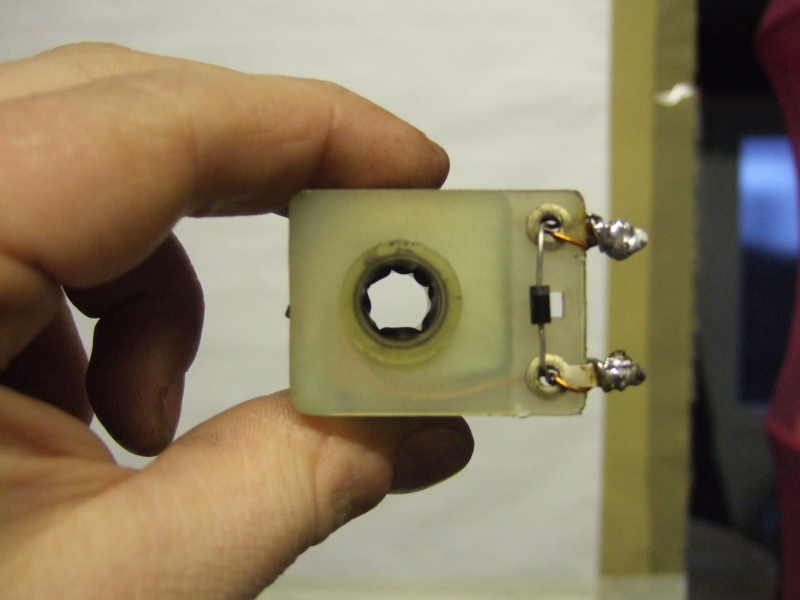

Another thing that has happened more than once, and in fact will continue to happen as long as pinball is played, is that the coils burn out. The coils are actually solenoids that fire a piston when they are activated. The solenoids in a pinball machine are electromagnetic coils with a metal piston inside that due to magnetism is forced out when electricity flows through the coil. The problem when the CPU or driver board is faulty is that they can leave a coil activated and as the electricity continues to flow through them they get hot and will eventually melt the plastic liner inside them, but before that, you can tell when they are about to fail or have already failed by testing their resistance.

Electrolytic capacitors like this have a working life of about ten years, so if mine was original to the table, which it appeared to be, then it was fitted in 1978 which makes it over 30 years old, three times its expected lifespan, so I replaced it as a matter of course. Don't even test it, change it.

It's worth noting that capacitor technology, like most things, has moved on and a replacement capacitor of the same or even a higher value will be much smaller in size than the original, so fitting it will need either a blob of silicone or a cable tie to fasten it to the power supply board in place of the older and larger one. Once I'd changed mine, all of the voltages were reading exactly as they should be, so I knew the CPU board was receiving the correct voltages.

Also on the power supply board are several fuses, and when first testing the game it's a good idea to pull these fuses out so that you are only powering up the power supply and none of the other boards or parts of table just in case there are problems elsewhere. One of these fuses in question was the G.I. fuse and as soon as I fitted a new one, the General Illumination bulbs came to life, well most of them anyway. An advisable modification for G.I. bulbs is to remove them all and replace them with a different bulb. Originally the table would have been fitted with #44s but they should all be replaced with #47s that will run much cooler and draw less power, therefore putting less stress on the bulbs, the circuits and the power supply. As a general rule the less heat generation you have in the game, the better.

Another advisable modification in the back box is to add a fuse to each of the two bridge rectifiers because it was essentially a design flaw not to include them in the first place, and one that Williams fixed in later machines. If either of the two bridge rectifiers (one for the lamp matrix and one for the solenoids) shorts out and the main fuse does not blow then the machine will set on fire, and that has happened more than once.

Another thing that has happened more than once, and in fact will continue to happen as long as pinball is played, is that the coils burn out. The coils are actually solenoids that fire a piston when they are activated. The solenoids in a pinball machine are electromagnetic coils with a metal piston inside that due to magnetism is forced out when electricity flows through the coil. The problem when the CPU or driver board is faulty is that they can leave a coil activated and as the electricity continues to flow through them they get hot and will eventually melt the plastic liner inside them, but before that, you can tell when they are about to fail or have already failed by testing their resistance.

The electricity is meant to flow around the strands of copper and travel around and around and around the single strands, but as the coil starts to fail the electricity finds shortcuts around the strands and it becomes less effective over time. When a coil is new it has high resistance and as it fails the resistance drops. Once it drops too low it will not be efficient enough to fire the piston and the flipper will not flip or the pop bumper will not pop bump. Once this happens the coil needs to be replaced.

Copyright © JamesOnline.net. All rights reserved.